No evidence is better than examples and applications of actually installed solutions at our customers. This solution database offers a selection precisely according to topics, tasks and parameters - ideal for decision support with additional information and photos.

Are applications missing or are tasks for industrial image processing not included? Please contact us directly at solutions@ziemann-urban.de

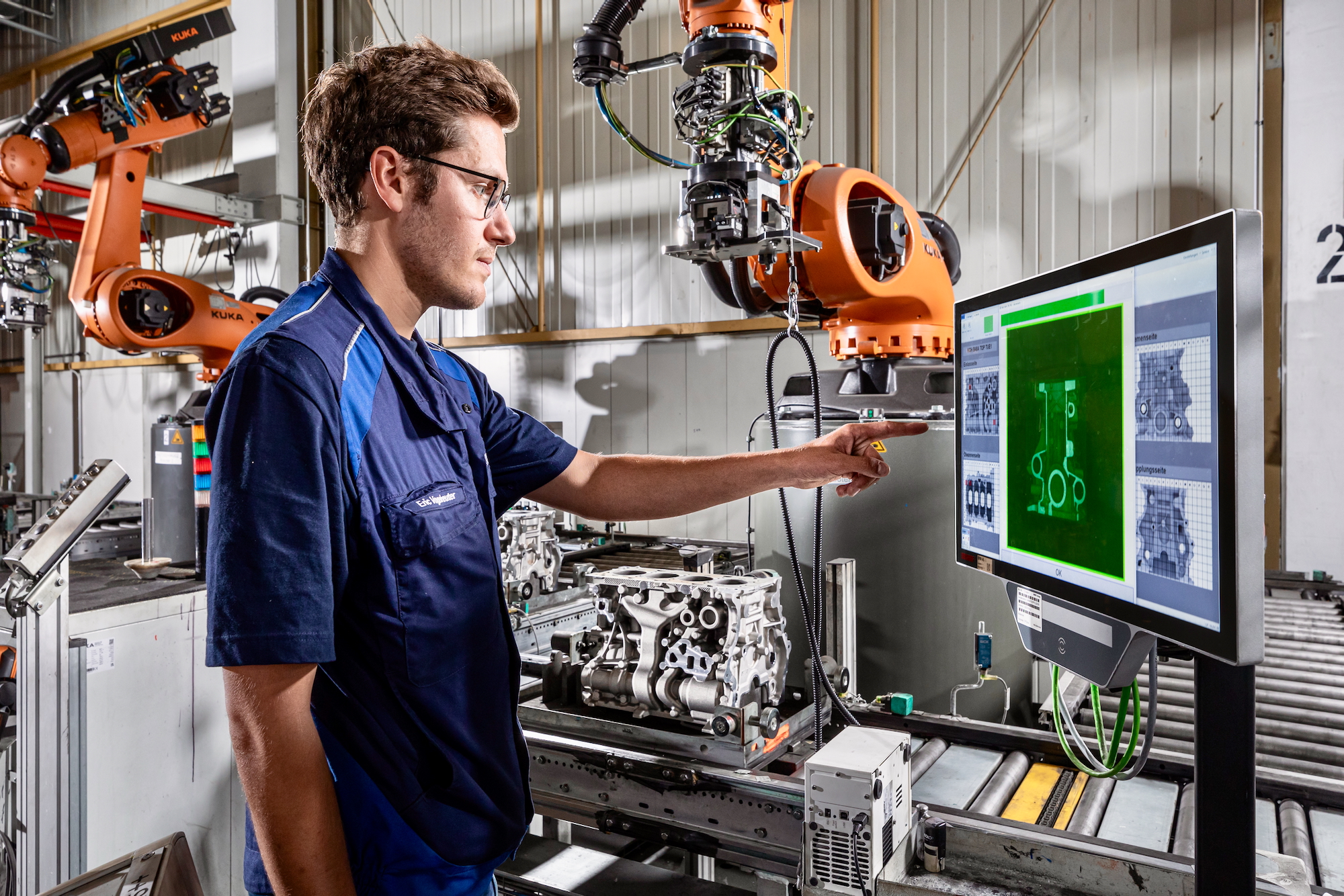

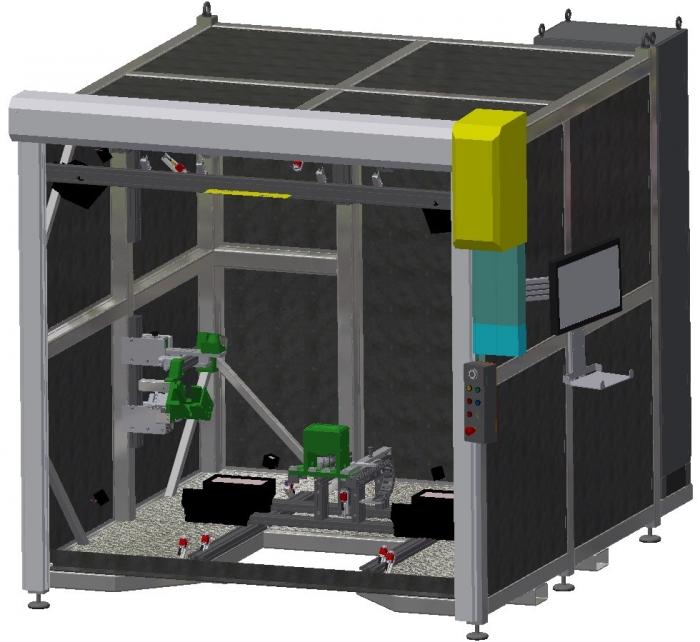

The system detects the 3D coordinates of engine raw cast Motor parts and communicates it to a robot that picks the parts and forwards them to a transport system.

Details

inline inspection with traceability

Details

inline inspection with traceability

Details

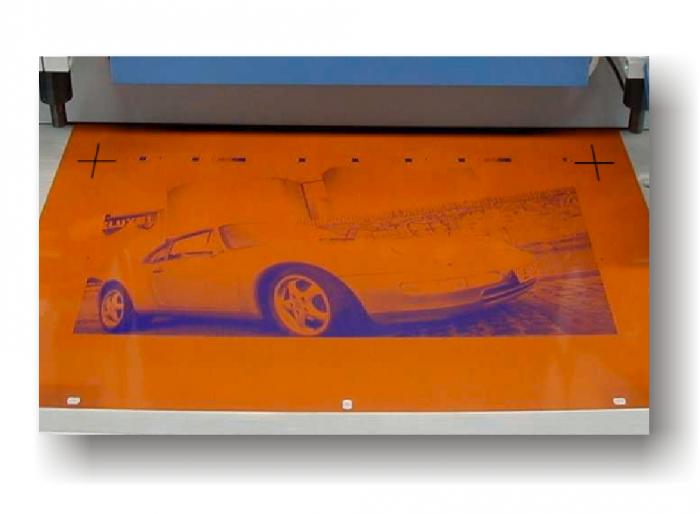

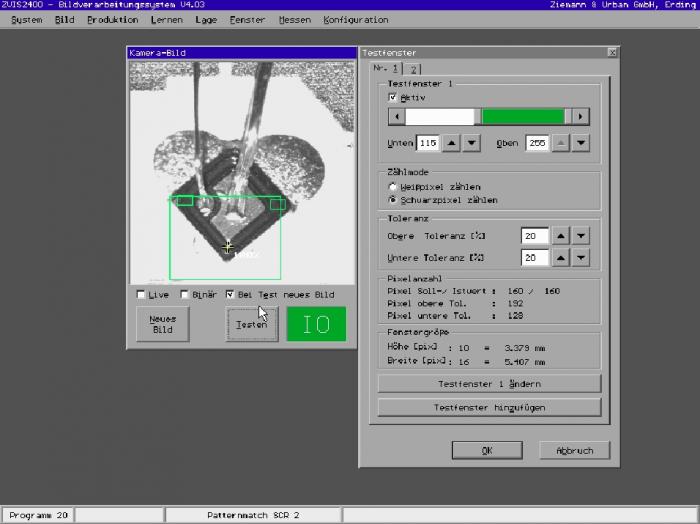

In the field of color printing each color needs a separate printing stencil. The printing motif on the single stencils often have a deviation up to several millimeters depending on the outer edges The

Details

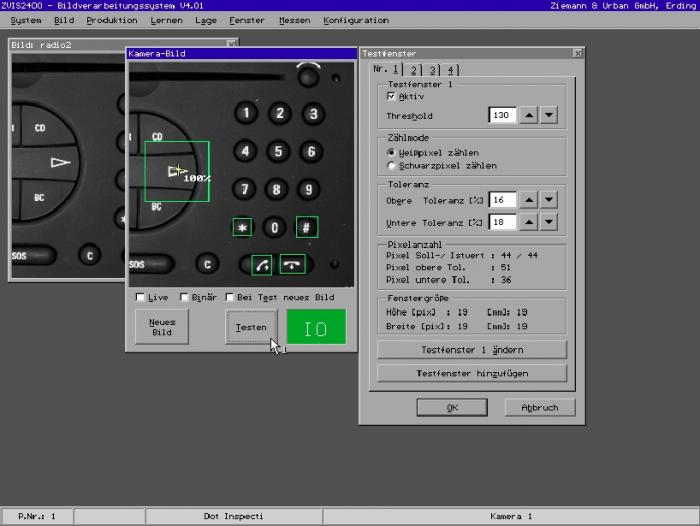

In a measuring cabin the system inspects the correct printing on the keys of a car radio cover using 4 cameras, 2 light sources and accordingly selected optical filters.

Details

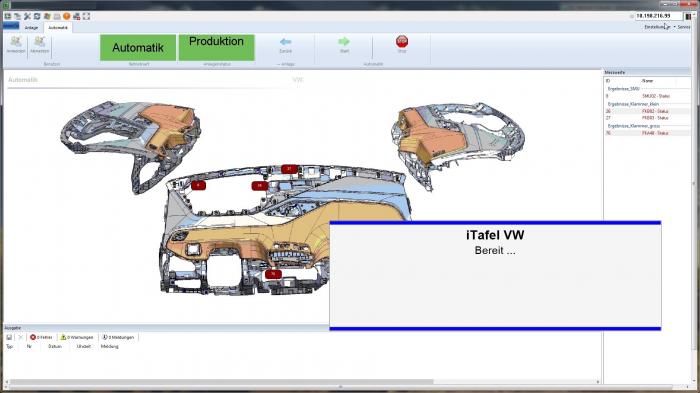

Presence of all clips after robot assembly

Details

Consistently high product quality with stable or falling costs is a key challenge for companies, including the BMW component plant in Landshut. With this in mind, an automated, AI-supported inspection

Details

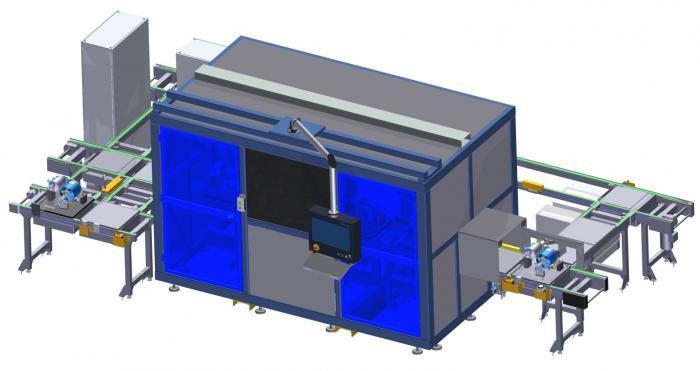

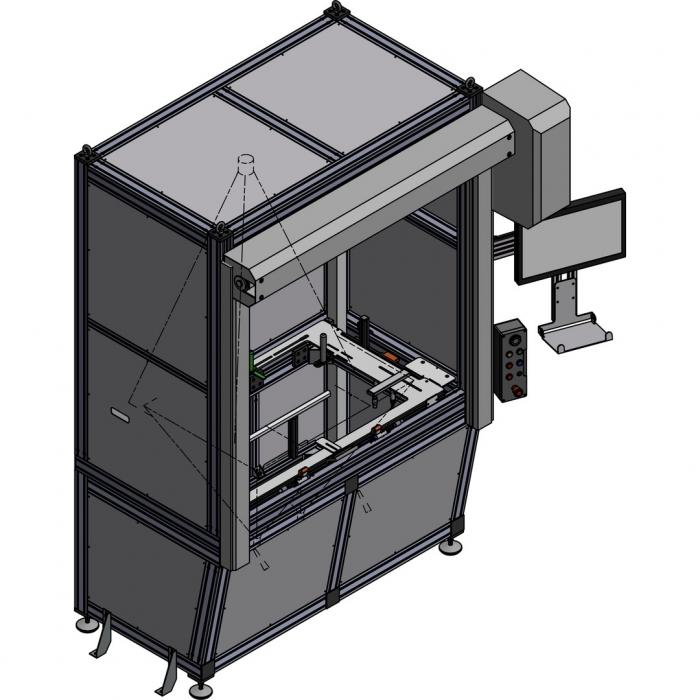

Complete system for inspection and handling of the examinees

Details

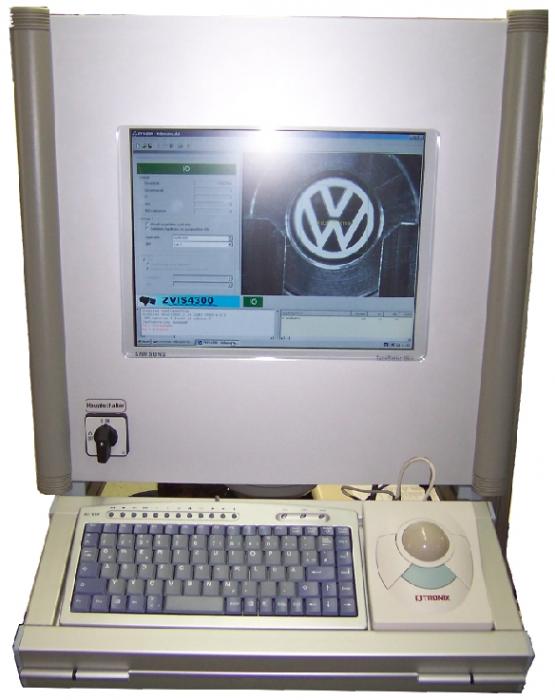

Fully automatic Vision system for rotational position detection in raw casted aluminum rims

Details

Testing & documentation of safety-related pressure sensitive mat in car seats

Details

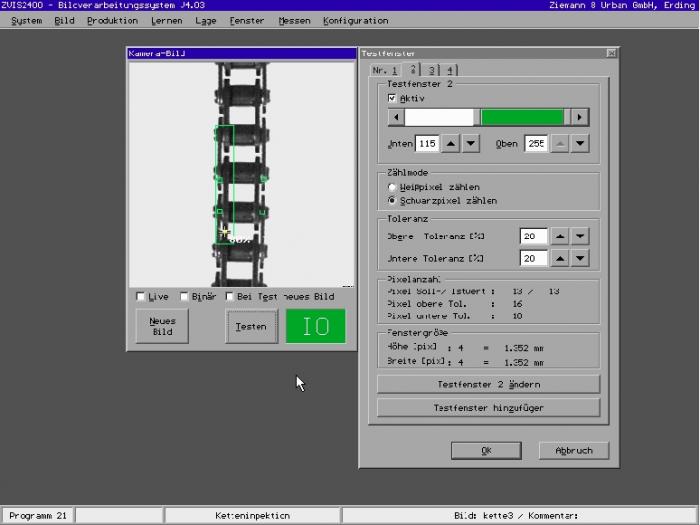

The system checks the completeness of industrial and automobile chains, which are produced continuously. During the control process the existence of all sideplates and rolls are checked.

Details

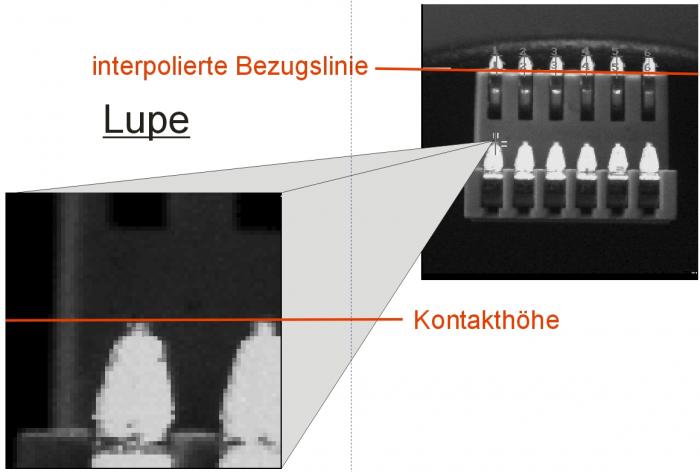

The Vision System is used for fully automatical measuring of pin spacings in miniature connectors.

DetailsFully automatic system to adjust fresnel lens plates to CPV solar chips, including electrical and optical test (EOL)

Details

Automatic Inspection and Colour Detection of test dishes

Details

Consistent quality of high-resolution images of complex components even under rough production conditions

Details

The system is designed to align round logos to the correct position and automatically inserts them in a car radio remote key.

Details

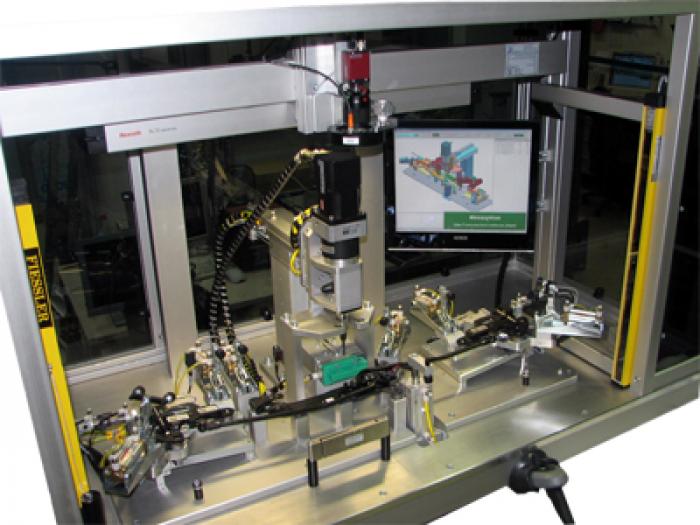

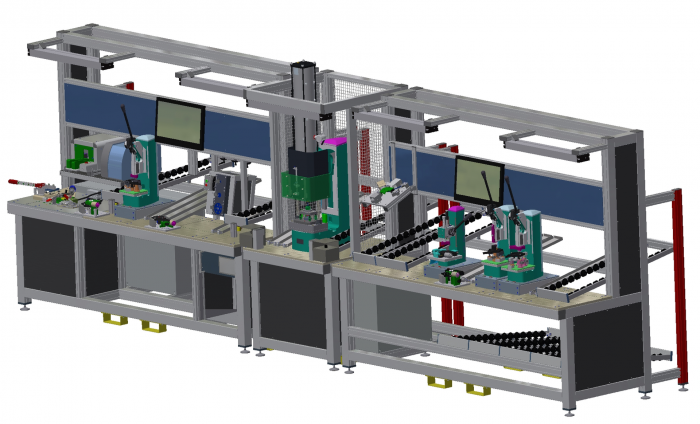

For a leading automotive supplier Ziemann & Urban delivered an end of line testing and adjustment system for 100% inspection of complex mechanical assemblies

Details

On a workpiece carrier circulation system, the inspection of plastic-coated steel pipes regarding dimensional stability, complete encapsulation and correct flow is performed.

Details

eMobility high-voltage connector for charging plugs with protection class IP67

Details

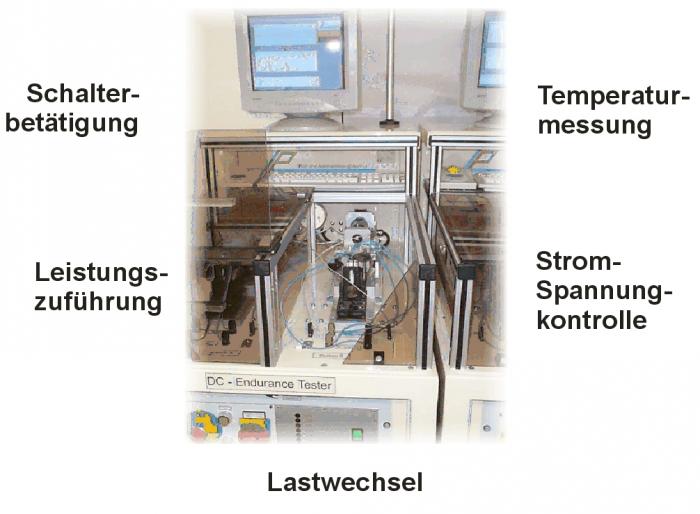

The endurance tester checks the life endurance of speed controllers of accumulator equipped power tools like electric drilling machines. Each module is designed as a double tester with the ability to

Details

Programming and operating via touchscreen and Graphical User Interface. integrated Vision system (optional for fully automatic process)

Details

Inspection system for Vermesung and leak testing of automotive exhaust systems

Details

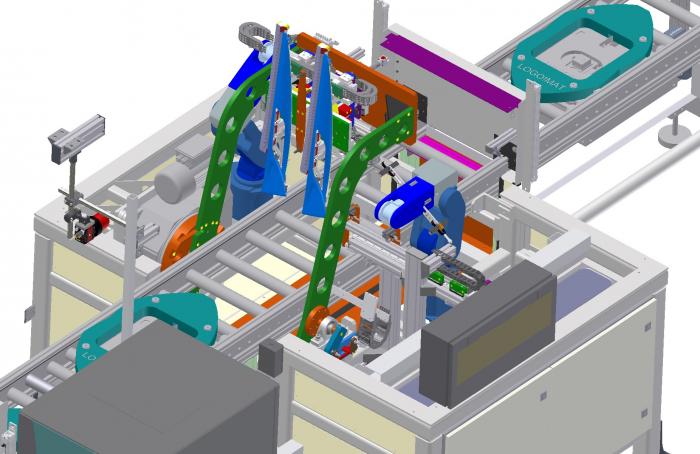

Automation with parts transport via workpiece carriers and contacting by SCARA robots

Details

The optical measurement of the latch unit is carried out during the movement in synchronization with micro-switches.

Details

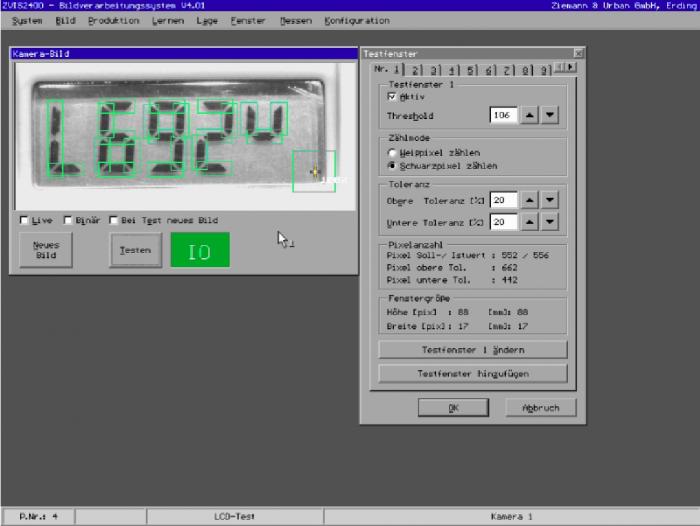

The vision system controls automatically the single segments of a LCD display. An LED area flood lighter is used for lighting.

Details

Ziemann & Urban is taking their customers one more step towards greater efficiency in production and product quality.

Details

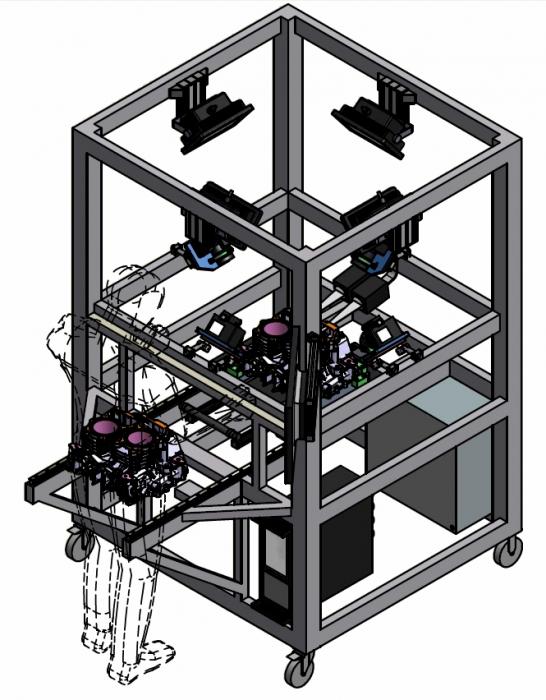

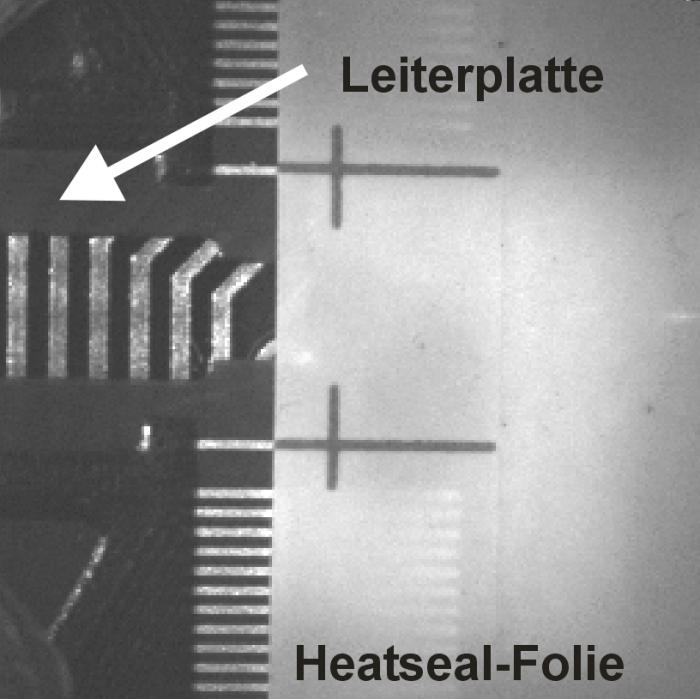

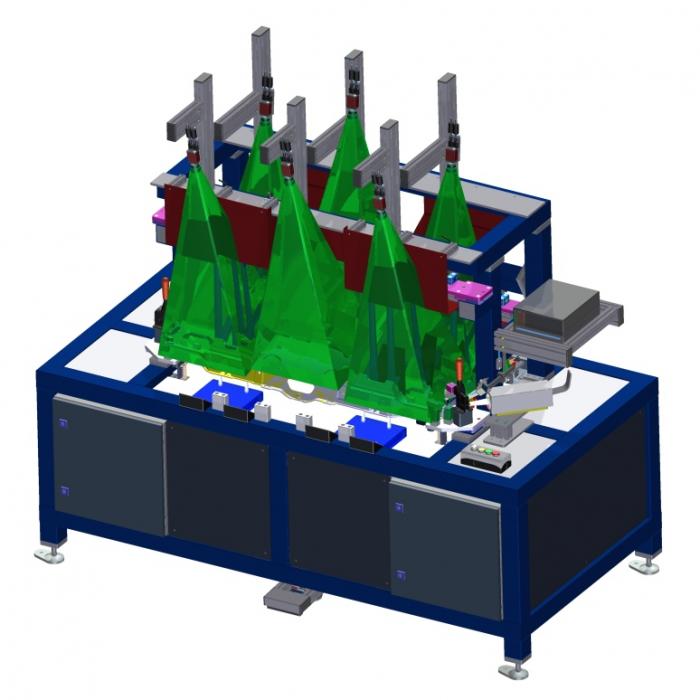

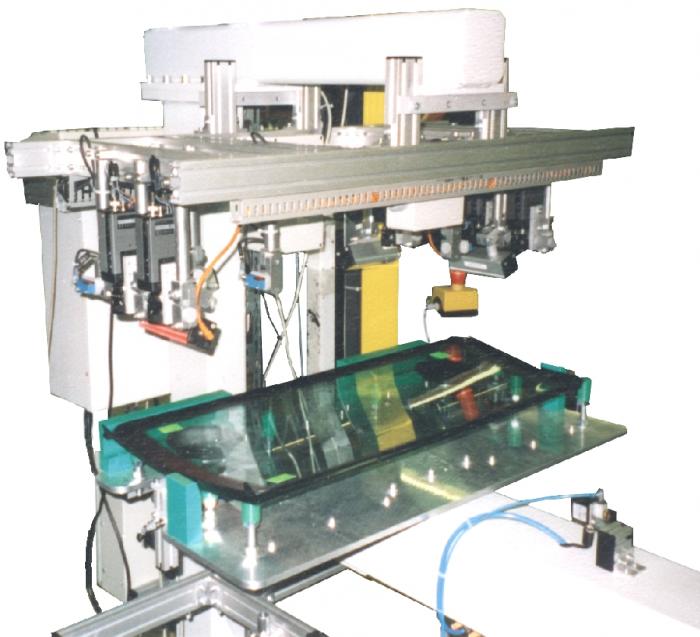

The vision system aligns the single components using 5 in x/y-direction movable cameras and 8 light sources.

Details

With three cameras and several switchable lightings the vision system tests and measures high frequency connectors and plugs.

Details

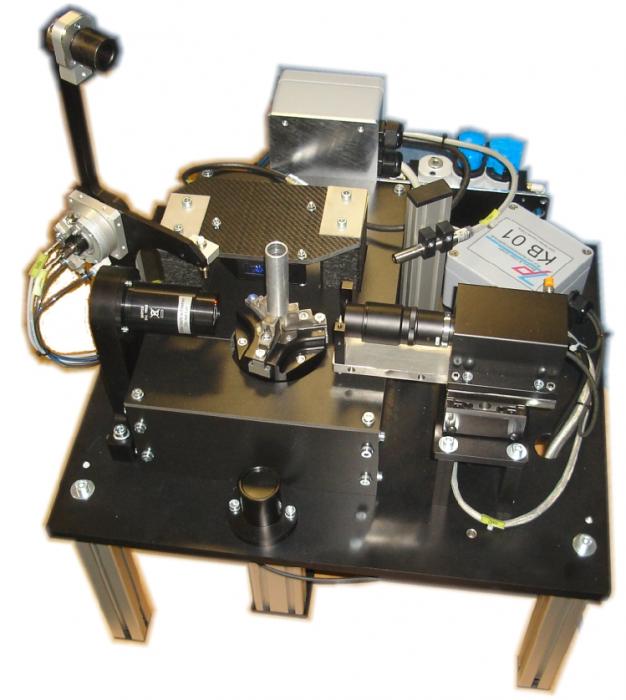

The inspection system measures the diameter and shape of the edges of round plastic parts with a measurement resolution of approx. 1µm

Details

Flexible, scalable, secure process, multilingual plug inspection with Ziemann & Urban

Details

The vision system in this application is used for the inspection of oil filter lids, which are assembled from two different components.

Details

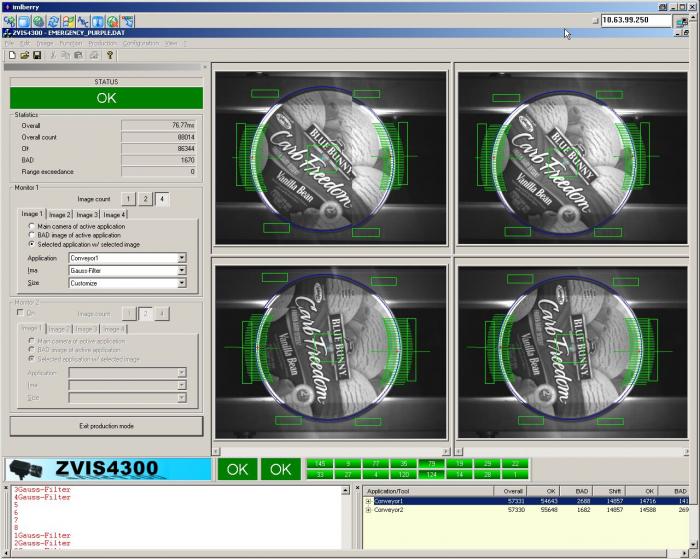

The system inspects the correct type and the correct position of in-mold labels in plastic covers on two conveyor belts with two parallel working Cameras.

Details

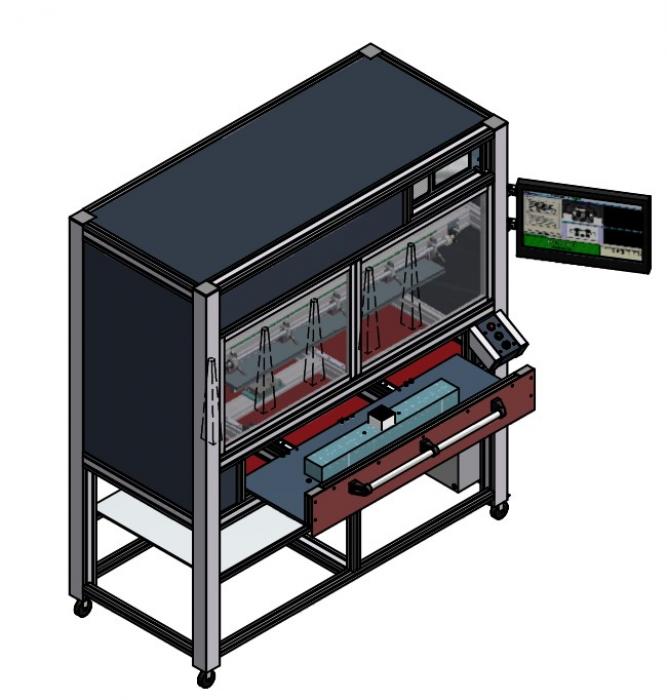

Mobile test station with manual loading via drawer and electrical contacting

Details

Inline Inspektion mit mehreren Kameras

Details

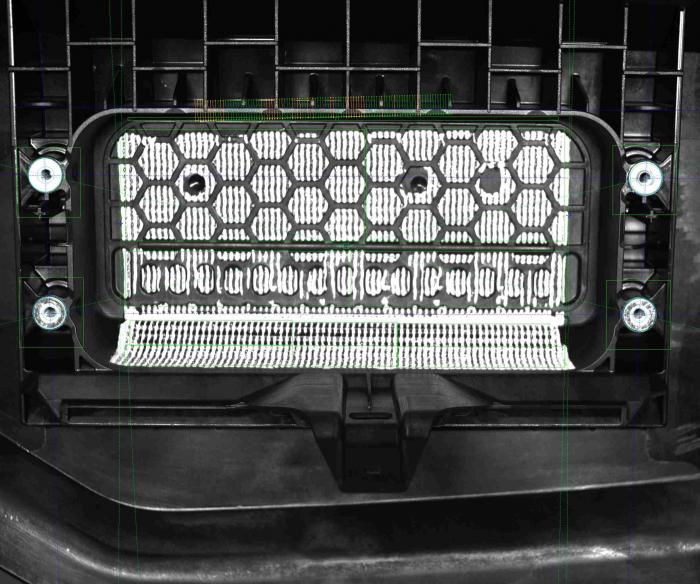

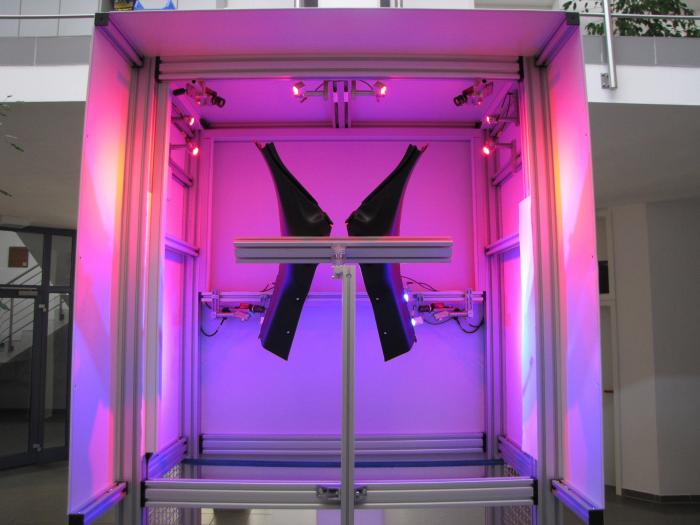

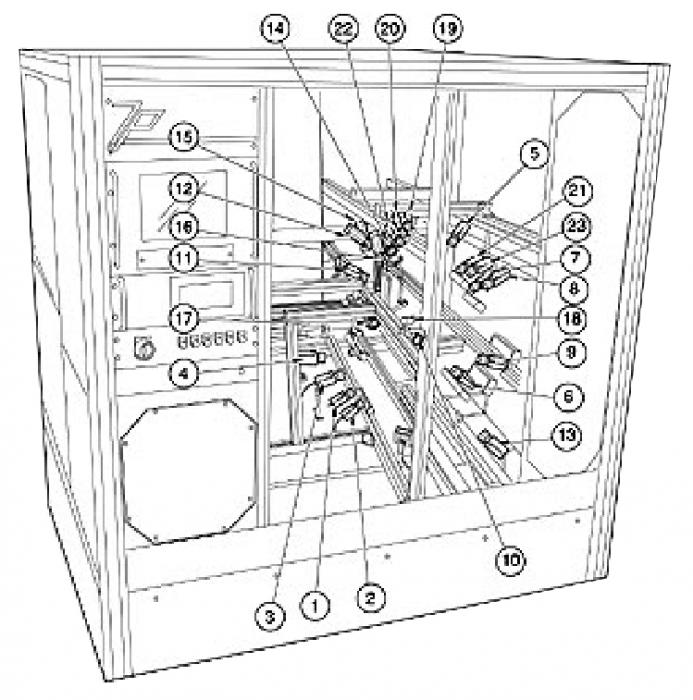

The inspection system tests up to five different types of air intake canals used in the automobile industry in a measuring cabin using 23 cameras and 18 light sources.

Details

The system is used for automatic optical inspection and sorting of compression springs.

Details

The tailor-made end-of-line test systems for car door panels from Ziemann & Urban enable a previously unique, integrated and process-proof inspection of lighting and interior according to the manufact

Details

For large quantities or large product variety, a highly accurate 100% measurement is often not feasible or viable.

Details

The automatic test equipment measures and inspects 7 different kinds of zylindrical molybdenum pins (diameter 1.5 mm, length 1.5 mm), which are necessary for diode production.

Details

Premium Testing for Premium Automobile

Details

Self-contained solution with automatic sorting and palletizing the OK Parts

DetailsA number of different cameras visually support the verification of completeness and quality of the interior configuration and ambiance lighting of produced door panels.

Details

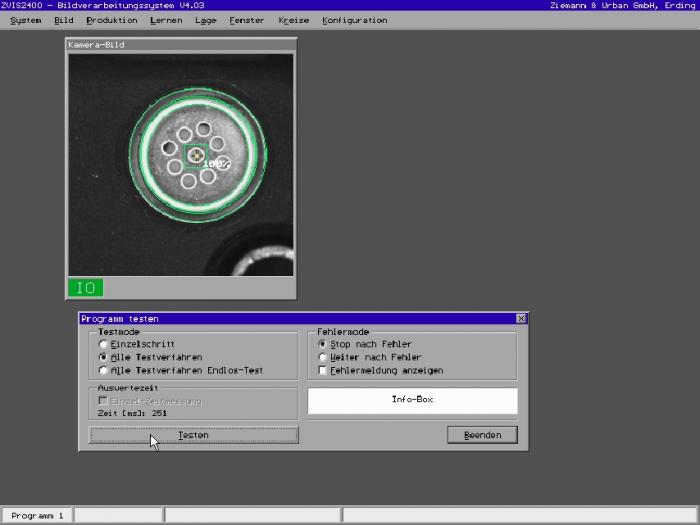

The vision system introduced here uses any possible polygon as a reference for position detection. This way the user is able to use optimal structures on the chip as a reference.

Details

During the assembly of car seats, the different components are connected using rivets and screws. This is done by a robot with 6 axes.

Details

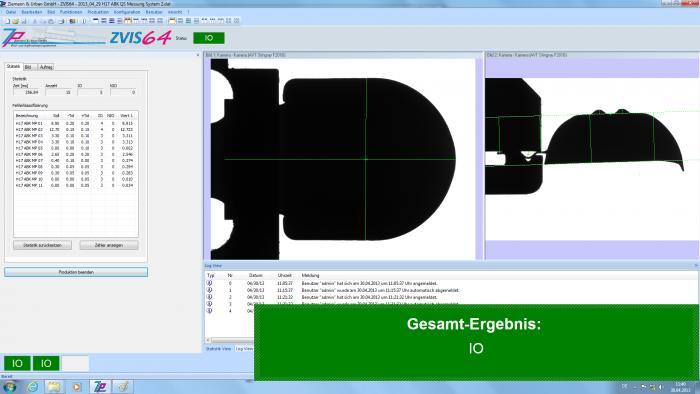

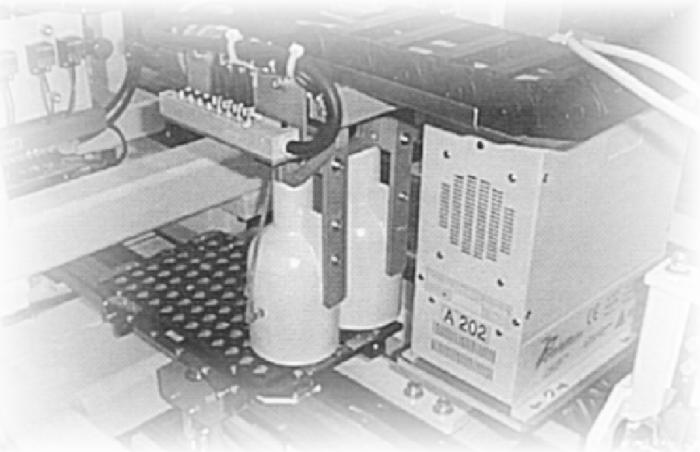

detailed quality inspection of 64 Pipette Tips in 10 minutes

Details

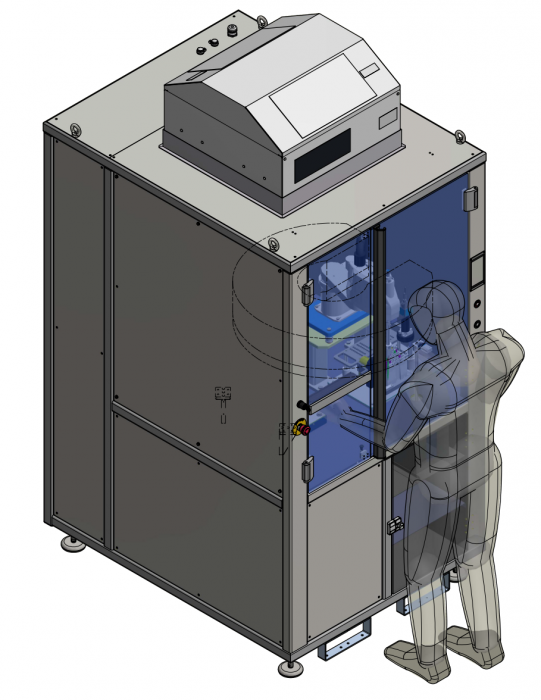

On an indexing rotary table with a diameter of 5.6 m and 12 nests, up to 8 motor vehicle window panes are presented to the vision system in a measuring cabin.

DetailsApplication example with success story from e-mobility project

Details

100% inspection of eMobility high-voltage contact for charging plugs with protection class IP67

Details

The vision system is used for inspection of pressure compensation units in motor vehicle control systems. In a flexible manufacturing module the pressure compensation units are tested regarding their

Details

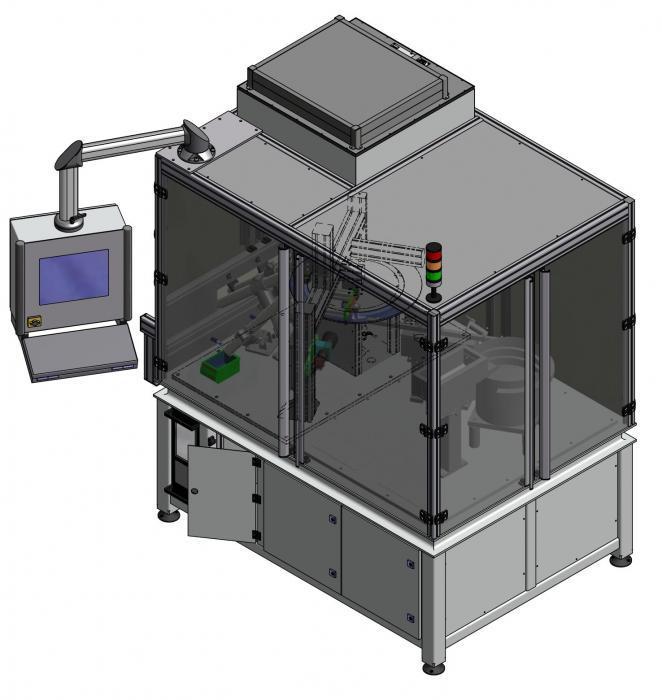

inspection cabin with automatic electrical contacting

Details

The vision system automatically controls the diameter and the pitch of a thread in a metal moulding.

Details

The automatic inspection system measures and controls three different types of press-in threaded bushes according to given tolerances.

Details

End of line testing of complete car instrument carriers with stationary test part and camera cloud

Details

The inspection system uses 2 cameras and 2 light sources to check up to 2 x 96 nests on work piece holders in an assembly line for existence of components and full moulding if applicable.

Details

With the high-performance ZU-SORT glass turntable system, companies are given complete control over their production with statistical evaluation - and the guarantee that only 100% OK parts have passed

DetailsAre applications missing or are tasks for industrial image processing not included? Please contact us directly at solutions@ziemann-urban.de