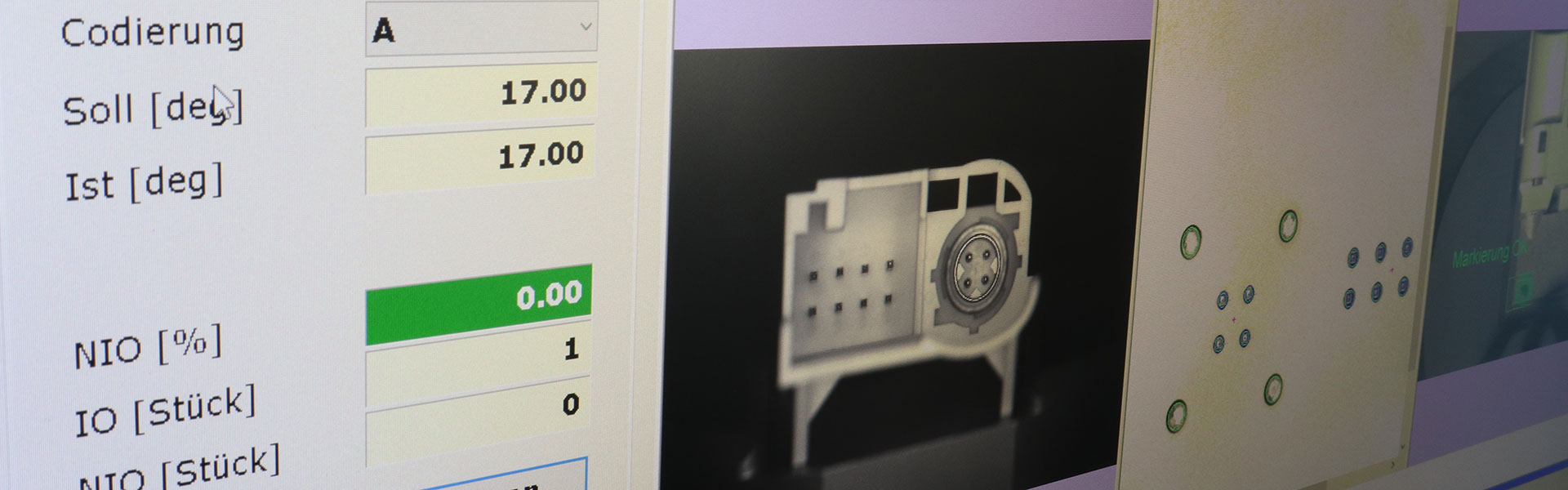

With this software, the test and machine sequences of a complete system can be created and different measuring devices (tactile, optical, camera) can be connected with each other. Of course, the results are visualised.

The in-house developed, powerful ZU-Control, which is continuously being further developed, is today one of the leading applications in the field of measuring technology software.

This software module offers ...

- ... Control of the test sequence

- ... Integration of different measuring devices (tactile, electrical, optical...) into the overall solution

- ... multi-sensor measurement technology: measurement, inspection and documentation of a wide range of physical variables with the aid of optical and tactile sensors and electrical measurement technology

- ... any combination of different measuring methods

- ... extensive possibilities for statistical evaluation and data storage/data output (everything that is checked/measured in the metrology software can be transmitted externally)

- ... linking of different sensors (e.g. dial gauges) in a 2D/ 3D (world) coordinate system

- ... Communication with higher-level controls via all common protocols and interfaces (field bus)

- ... Service menu with extensive diagnostic/test modes - Optional storage of measured values on customer servers or databases

- ... any combination of several of the above-mentioned modules (measurement technology/image processing)

- ... almost any number of image processing and measuring units in the production process can be centrally processed and evaluated with ONE control technology module - flexible and easy to expand or change at any time.

A large selection of solutions with "ZU-Control" can be found in the solution database.